Everything about Precision Laser Cutting

Everything about Precision Laser Cutting

Blog Article

In relation to modern day production, the precision and performance of laser slicing technological innovation are definitely video game-changing. Laser chopping equipment have revolutionized industries by giving a method of slicing components with unparalleled accuracy. In case you’ve at any time marveled on the intricate types on metal or puzzled how elaborate designs are developed so seamlessly, it’s often the function of an industrial laser chopping machine.

Enable’s begin with the basic principles: a laser cutter is actually a Device that works by using a laser beam to chop resources. This beam is unbelievably concentrated and generates large temperatures to melt or vaporize the material, making specific cuts. Unlike common solutions, which could use mechanical blades, a laser cutter offers a standard of accuracy that is sort of unmatched. Consider attempting to carve a delicate pattern which has a hammer—Evidently, a laser cutter is a good deal far more refined!

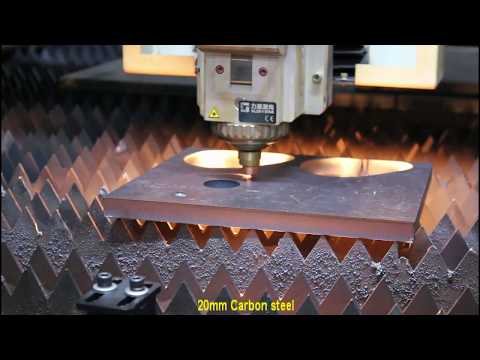

Industrial laser slicing takes this technologies to another stage, delivering options for large-scale functions. These machines are designed to manage significant resources and significant creation volumes, making certain that even quite possibly the most demanding jobs are accomplished with large efficiency. Visualize it because the difference between employing a precision knife for fragile paper crafts and a powerful saw for reducing as a result of thick wood.

The Greatest Guide To Laser Cutting Services

In the world of CNC laser slicing, the “CNC” means Laptop or computer Numerical Manage. This technologies allows for automatic and hugely specific cuts by following digital types. If you’ve at any time utilized a computer to attract and after that seen that drawing arrive at life, CNC laser slicing is effective in an identical way, translating electronic layouts into Bodily cuts. It’s like using a Digital designer Together with the precision of a laser.

In the world of CNC laser slicing, the “CNC” means Laptop or computer Numerical Manage. This technologies allows for automatic and hugely specific cuts by following digital types. If you’ve at any time utilized a computer to attract and after that seen that drawing arrive at life, CNC laser slicing is effective in an identical way, translating electronic layouts into Bodily cuts. It’s like using a Digital designer Together with the precision of a laser.The smart Trick of Laser Cutting Machine That Nobody is Talking About

Precision laser slicing isn't just about making cuts; it’s about creating them suitable each and every time. The laser can be altered to achieve diverse depths and widths, ensuring that each Minimize is precisely exactly where it has to be. This is certainly essential for apps exactly where even a slight deviation could lead to important troubles. Think of it for a surgeon’s scalpel, the place precision is not only crucial but Definitely vital.

Precision laser slicing isn't just about making cuts; it’s about creating them suitable each and every time. The laser can be altered to achieve diverse depths and widths, ensuring that each Minimize is precisely exactly where it has to be. This is certainly essential for apps exactly where even a slight deviation could lead to important troubles. Think of it for a surgeon’s scalpel, the place precision is not only crucial but Definitely vital.Laser cutting machines comes in different sorts, each customized to distinct wants. Whether You will need a modest desktop design for passion jobs or a huge industrial equipment for factory use, there’s a laser slicing Alternative around in your case. These machines fluctuate in ability, pace, and capabilities, so it’s vital that you pick the right a single in your individual software.

Sheet metallic laser cutters undoubtedly are a Unique classification of laser chopping machines made especially for cutting metallic sheets. They're broadly Employed in industries ranging from automotive to aerospace due to their power to deal with metallic with precision and speed. Photo a sheet of steel just like a blank canvas, and also the laser cutter given that the artist who produces elaborate and beautiful designs with incredible accuracy.

Laser slicing solutions are Yet another significant element of this know-how. Not Every person desires to take a position in their unique laser cutting device, especially if they only need occasional cuts go here or lack the House for this sort of gear. Many companies present laser reducing products and services in which you can ship your patterns and have them Reduce with significant precision. It’s like outsourcing your artwork to a talented Qualified.

Laser slicing methods integrate various elements to deliver the desired effects. From the laser supply on the cutting bed, along with the Command software program, just about every Section of the procedure works collectively to be sure a flawless Procedure. It’s a bit similar to a symphony orchestra, in which Each and every musician has a particular part, and only by Functioning together do they produce a harmonious general performance.

With regards to laser cutting technological innovation, the evolution has been fast and extraordinary. Initially made use of mainly for cutting metals, these machines now tackle a wide array of products like plastics, wood, and in some cases fabrics. This flexibility would make laser slicing technologies a worthwhile Device in many industries. Envision using a Swiss Army knife that may tackle almost any content—this is what fashionable laser chopping technology provides.

The accuracy of laser reducing equipment is really remarkable. They might cut supplies to inside of microns from the intended style, ensuring that even the most intricate information are preserved. This degree of precision is especially valuable in industries in which specific measurements are important. Imagine it because the distinction between a tailored match and off-the-rack outfits—the match is simply excellent each and every time.

Examine This Report on Laser Cutting Systems

A further advantage of laser cutting technological know-how is its performance. Unlike regular reducing strategies that might need a number of ways or applications, laser cutting usually completes the job in one go. This not just hurries up manufacturing but additionally lessens product squander. It’s like using a substantial-velocity teach that will get you to your destination rapidly and competently with no unnecessary stops.While in the Laser Cutting Technology context of industrial purposes, the robustness of laser reducing devices is crucial. These equipment are designed to endure the demands of ongoing operation, normally managing 24/seven in large-volume configurations. Their sturdiness guarantees reliable general performance and dependability, that's essential for protecting production schedules. It’s like possessing a heavy-duty truck that reliably provides products working day following day.

Among the list of outstanding aspects of laser reducing is its ability to develop clear and exact edges. This decreases the necessity for put up-processing, such as sanding or ending, that may be time-consuming and expensive. The end result is a clean, finished product or service that often requires nominal further operate. Envision ending a craft venture without glue spills or rough edges—it’s that cleanse!